X500 III Pro Laser Cutter

Advanced Laser Cutting Quality

The LaserPro X500III Pro is engineered for professional use and is packed with user-friendly features. The X500III Pro laser cutter will perform both cutting and engraving tasks admirably, a versatile system that offers high product performance in terms of both productivity and feasibility.Available in 100W, 130W or 150W

IDEAL FOR :

• Cutting wood, acrylic, MDF and other materials • Engraving • Personalised items • Gift items• Key rings • Models • Paper Products etc.

X500 III Pro Laser Cutter Features

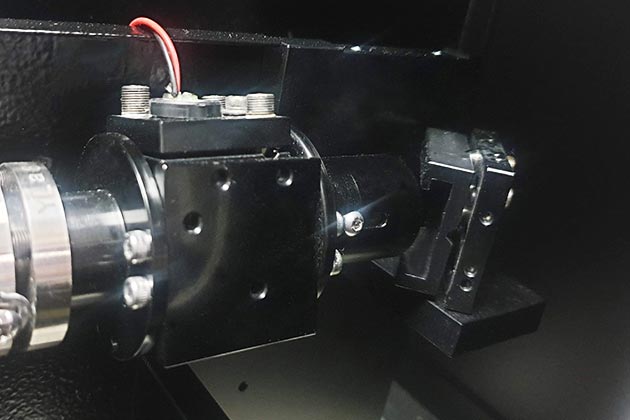

Beam Xpander

X500III Pro includes one 1.6X beam expander for uniformity of line width that presents outstanding quality and reliability.

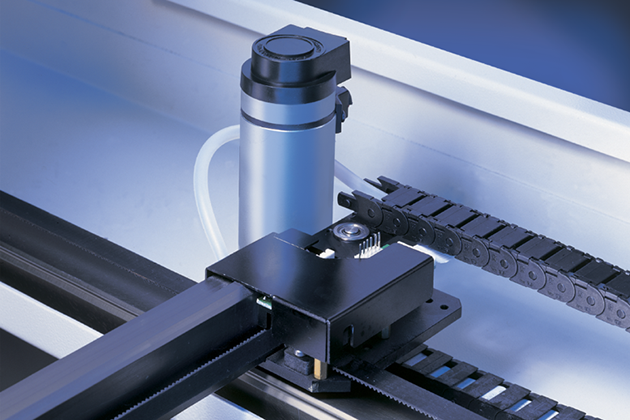

NEW DESIGN OF X500III PRO CARRIAGE

Advanced X500III Pro carriage design to increase the stability of carriage movement, elevate the performance of X500III Pro.

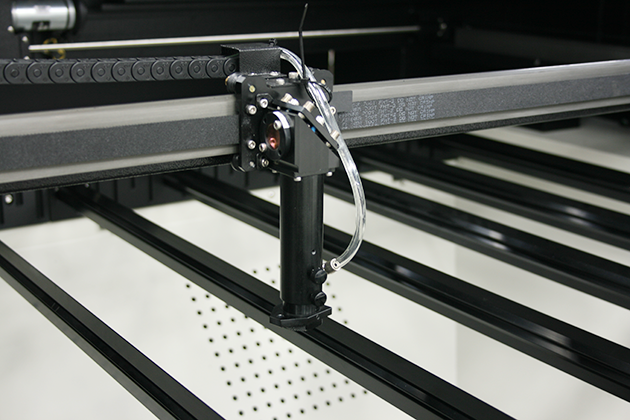

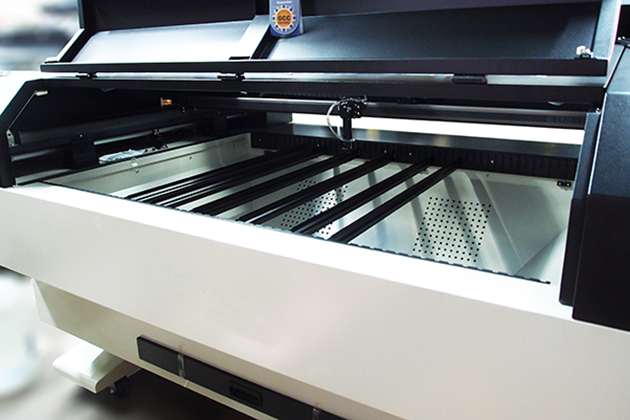

KNIFE-SHAPED CUTTING TABLE

Unique cutting table with tipped bars that can be easily adjusted without tools to create different levels of working depths. The cutting table of X500III Pro reduces laser reflections and delivers clear cutting edge.

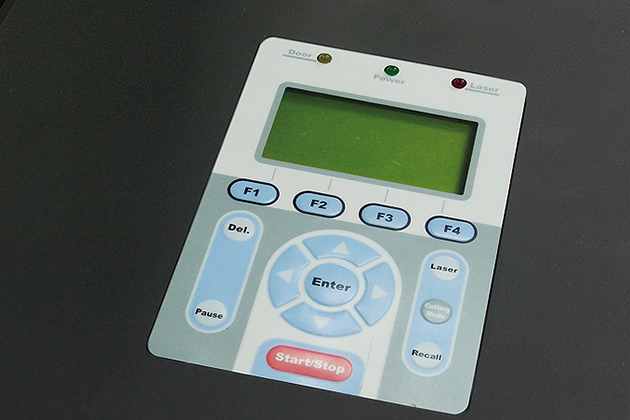

INTUITIVE CONTROL PANEL INTERFACE

A control panel with coherent hot-key design and graphic icon displays that allows you to directly change the laser parameter setting and set jobs to repeat unlimited times, queue job, delete jobs, and more.

CLOSED-LOOP DC SERVO TECHNOLOGY

X500III Pro utilises a high-speed closed-loop DC servo motor technology that guarantees fast and precise carriage movement to ensure exceptionally accurate cutting outputs.

KEY SWITCH & EMERGENCY STOP

Key switch safeguards the machine from unauthorized use. A prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

DRAG-N-PLAY

The “Drag-N-Play” feature greatly reduces complex set-up procedures and allows users to directly drag the lens carriage to the starting point of a job.

VERSATILE ENGRAVING AND CUTTING CAPABILITY

X500III Pro delivers high cutting quality with LaserPro’s unique Laser firing control technology. X500III Pro can cut through 20 mm acrylic in a single pass. Better than that, the grayscale technology allows X500III Pro to process 256-level grayscale images with vivid engraving quality.

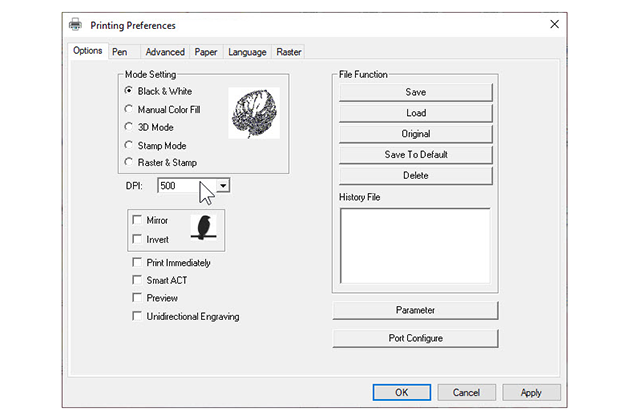

INNOVATIVE WINDOWS DRIVER

LaserPro Windows-based driver provides powerful functions, such as SmartCENTER™, Air Assist by Pen, Dithering Patterns and more to reduce set up time and make easy adjustments to achieve marvellous output quality.

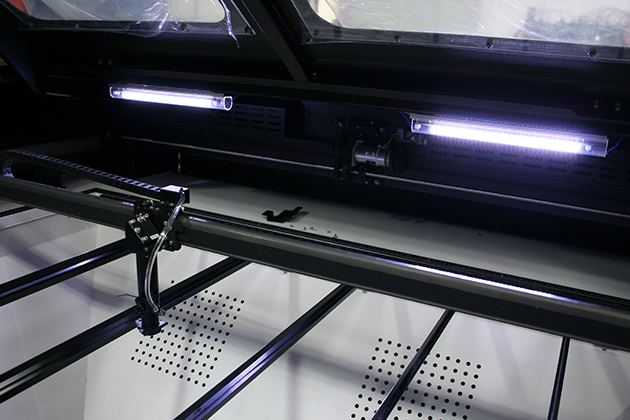

SMARTLIGHT

A Built-in LED light module illuminates the working space and makes every engraving detail easy to see.

PASS-THROUGH FRONT TO REAR DOORS (OPTIONAL)

A design with doors on both ends to accommodate extremely long working pieces, a front door without the need for a screwdriver.X500III Pro Specifications

Work Area

51.1 x 36.1 in (1300 x 916mm)

Maximum Part Size (WxLxH)

w/o Cutting Table

1346 x 916 x 55 mm (52.9 x 36.0 x 2.1 in.)

All doors open

53 in x ∞ x 1.1 in (1346 x ∞ x 30mm)

With Honeycomb Cutting Table

1240 x 818 x 30 mm (48.8 x 32.2 x 1.1 in.)

With Grid Cutting Table

1325 x 889 x 30 mm (52.1 x 35 x 1.1 in.)

Dimensions ( W x D x H)

74.8 x 55.1 x 47.2 in (1900 x 1400 x 1200mm)

Laser Source

Sealed CO2 Laser

Drive

Closed-loop DC servo control

Maximum Motor Speed

40 IPS

Speed Control

Adjustable from 0.1-100% (Up to 16 colour-linked speed settings per job)

Power Control

Adjustable from 0-100% (Up to 16 colour-linked power settings per job)

Distance Accuracy

0.254 mm or 0.1% of move, whichever is greater

Z-Axis Movement

Automatic

Z-Axis Movement

Automatic

Computer Interface

Standard printer port and USB port

Compatible Operating Systems

MS Windows

Memory Buffer

32 MB standard

Safety

Class 3R for red pointer

Facility Requirements

Operation Voltage

200-240VAC, 50/60Hz auto-switching, Max.10A

Water Chiller

External water chiller required

Power consumption

1250-2000 Watts

Air Exhaust System

An external exhaust system with a minimum flow rate of 2000m3/h (CFM 1177 ft3/min) is required, 3.8kPA negative pressure (Pure-Air PA-2000FS-IQ @ 8" exhaust port)

Optional Items

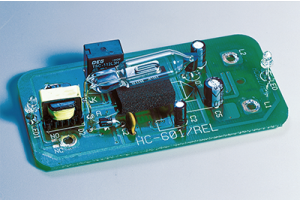

External Interface Control Board

The External Control Interface Board is an optional item that allows users to set up GCC LaserPro laser engraving and cutting systems for communication with external devices such as odour reduction units, robot arms, and others via a 5V or 12V signal to form an automatic production line. Another useful practice applies in certain working environments when users are required to set up an extra remote interlock control or when laser machines are allowed to be switched off if a security device is triggered

Grid Cutting Table

The grid cutting table is an ideal pal for laser cutting. It lifts the workpiece off the work table from hitting by laser reflection while supporting it with a reinforced grid design. The dust and vapour created during laser cutting are then taken away effectively through the grid by a down vacuum funnel exhaust. Rather than handling rigid materials, the grid cutting table also helps to fix flexible materials with the aid of a down vacuum to keep constant focus distance and consistent cutting results. A clean and better

SmartPRINT™

SmartPRINT™ software features powerful functions, an intuitive interface, and a built-in GCC LaserPro laser parameter setting for both Mac and Windows users. SmartPRINT™ provides clipart libraries, compatibility for various file formats, and advanced graphic functions such as Auto Trace Image Contour, Convert to Rhinestone, Generate Puzzle, and many more. Also, the additional text justification and sizing options can convert stroke to the path.

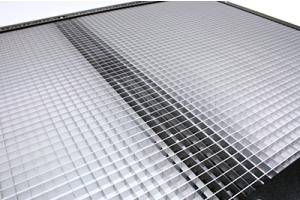

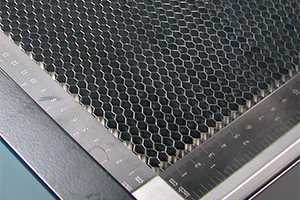

Honeycomb Table

A honeycomb table is a tool for laser cutting, especially when cutting materials into small pieces. A Honeycomb table lifts the workpiece off the work table and prevents the laser from hitting the object by laser reflection while supporting it with a honeycomb cell design. The dust and vapour created during the laser cutting are taken down through the honeycomb cell by a down vacuum funnel exhaust. The honeycomb table also helps fix flexible materials with the aid of the down vacuum to keep constant laser focus.

SmartGUARD™ Fire Alarm (Patented)

Laser engraving and cutting operation using the SmartGUARD Fire The alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut down the operation system immediately.

Air Compressor

A specially designed Air Compressor, by using an oil-less diaphragm, helps you eliminate the harmful and damaging side effects of moisture on the laser optics. In addition, it provides the optimal air pressure when laser engraving and cutting to blow away vaporized particles and prevent overheating, keeping lenses and mirrors clean for longer laser life.

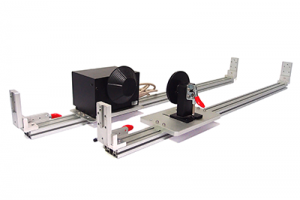

Rotary Attachment-X500III Laser Cutter

Allows the laser system to perform at another level! By using the rotary attachment, engraving on cylindrical or round objects is now possible. This option uses a fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixtures available. The minimum inner/maximum outer diameter and length of the working object is 7mm / 120mm and 1020mm respectively. Its maximum weight should not exceed 4kgs.

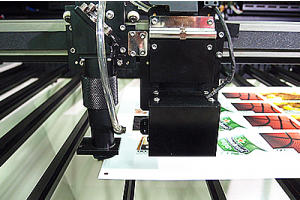

AAS Contour Cutting Device - X500III (Patented)

Developed by GCC LaserPro, AAS is an exceptionally user-friendly operation that offers accurate and faultless contour cutting by automatically tracking the position of graphics.Note: Working area and engraving speed will be reduced when AAS module is installed.

Air Extraction System - T500, X500III

To accomplish strong vacuum ventilation requirements for industrial application, GCC LaserPro X500III and T500 are recommended to supply a more powerful air extraction unit with an 8” opening to reach the optimum cutting quality. The air extraction system is powered by a maintenance-free turbine that takes out the fume and dust generated during laser processing efficiently and effectively, leaving a quality cutting edge and clean operation environment.